Customer: Germany

Date of implementation: Q1, 2021

Project goal: Ball Dropper for a variable number of balls

The production of some aerosols - especially paints or technical aerosols - requires throwing metal or glass balls into the can. This step is required because a canned product is a mixture of several ingredients and it is often recommended that you shake the can before dispensing the product to ensure the ingredients are well mixed.

Depending on the parameters of the product, it may be necessary to throw in more than one ball. In the case of our implementation, the client required throwing four balls into the can with a capacity of 60 cycles per minute. The customer expected an automatic change in the number of balls - without the need for many operations.

Workflow

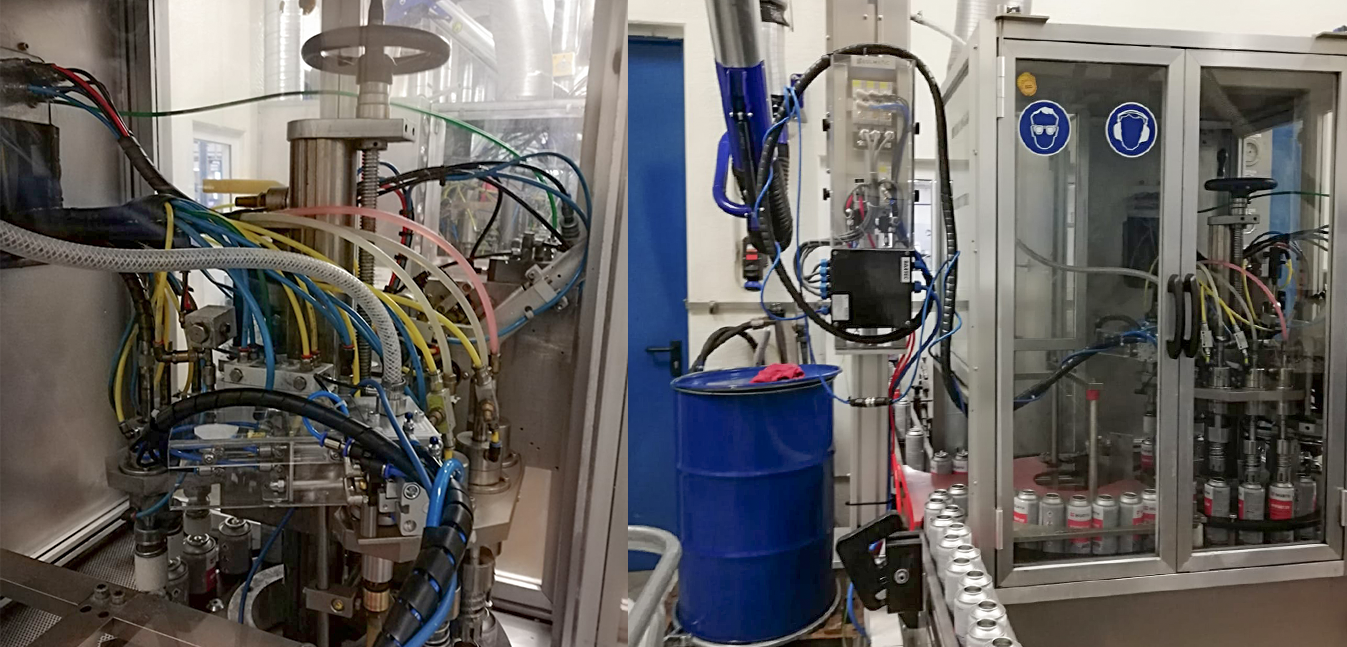

Pellet makers are usually installed in front of or inside Automatic Rotating Modules (AMR), as one of the modules before pouring the product into the can. In this case, the client already had AMR and commissioned us to produce only a pellet press, which he could install inside.

So far, the pellet pellets produced by us could as standard throw up to three balls, so it was necessary to take a new approach to this device. Through internal meetings, we managed to develop the concept of a modular ball throwing system that could be freely configured and expanded according to the desired number of balls thrown in. The entire throwing system is a proven solution for years, but we have carried out detailed tests as standard. We do not skip this stage in any case - both when implementing a new and proven solution.

We have included ultra-sensitive counting sensors in the ball machine, thanks to which we were able to maintain its capacity at 60 pieces per minute - regardless of the number of thrown balls in one cycle. In addition, we equipped the device with a control cabinet, and the modules counting the number of balls - with control actuators. Thanks to this changing the number of balls thrown is done with one switch.

Effect

We installed the finished device on the customer's production line and combined it with the control logic. Thanks to high flexibility in the number of balls thrown in and a large maximum number of balls thrown in the customer is able to fill a wider range of products with complex recipes. In the aerosol contract manufacturing industry, this is crucial and allows us to offer services to a wider group of customers.

A very important issue in the production is also the time to change the machines to work with a new product or a different size of aerosol cans. Often the installation of a new machine or device is associated with additional time necessary for its conversion - and with large lines this time can even reach several hours with old technologies. In the case of our ball machine the implementation of the new device remained unimportant for the time of retooling, because it takes less than 10 seconds to change the number of balls thrown in.

Machines used in the project